Mastering Plastic Extrusion Die Design: Exploring Pipe/Tubing Forming Die by Boyu Extruder

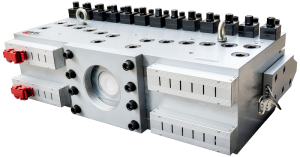

In the realm of plastic extrusion, the design of the die plays a pivotal role in shaping the final product. Boyu Extruder‘s expertise in plastic extrusion die design extends to the realm of Pipe/Tubing Forming die, offering unparalleled precision and efficiency in continuous extrusion processes.

Understanding Pipe/Tubing Forming Die Design

The Pipe/Tubing Forming die is a specialized type of plastic extrusion die that enables the production of thick-walled tubes and pipes in a continuous manner. This die design shares remarkable similarities with the die used in blown film extrusion, albeit with some distinct features. The key difference lies in the gap between the inner mandrel and the outer die wall, which is tailored to accommodate the specific requirements of tubing and pipe production.

Optimizing Cooling Processes for Superior Results

In Pipe/Tubing Forming die design, the cooling process of the polymer melt is a critical aspect that directly impacts the final product’s quality. Boyu Extruder’s innovative designs incorporate advanced cooling mechanisms, utilizing water baths or multiple cooling fans to efficiently cool the extruded material. This meticulous cooling process ensures uniformity and consistency in the thickness and dimensions of the produced tubing or pipes, enhancing overall product quality.

Streamlining Post-Extrusion Handling

After the extrusion process is complete, the flexible tubing is wound onto large spools, ready for further processing or distribution. In the case of rigid tubes, they are cut into preset lengths and stacked for easy handling and transportation. Boyu Extruder’s Pipe/Tubing Forming die designs are optimized to streamline post-extrusion handling, maximizing efficiency and minimizing production downtime.

Conclusion

Boyu Extruder’s commitment to excellence in plastic extrusion die design shines through in their Pipe/Tubing Forming die solutions. With meticulous attention to detail and innovative cooling mechanisms, Boyu Extruder ensures superior results and enhanced efficiency in continuous extrusion processes. Industries can trust Boyu Extruder’s expertise to deliver precision-engineered die designs that meet the demands of modern manufacturing, setting new standards for quality and performance in plastic extrusion.