Boosting EV Production with DEKUMA’s TPV Pipe Extrusion Technology

In the rapidly growing electric vehicle (EV) market, TPV pipe extrusion is becoming a key technology for fluid management systems. Thermoplastic Vulcanizate (TPV) combines the benefits of rubber and plastic, making it the ideal material for fluid pipelines in EVs. With the increasing demand for lightweight, durable, and eco-friendly components, TPV offers excellent performance in the extreme conditions that EVs often face, including high temperatures and pressure. As DEKUMA EV production scales, TPV pipe extrusion is playing a critical role in meeting industry demands for advanced, sustainable materials.

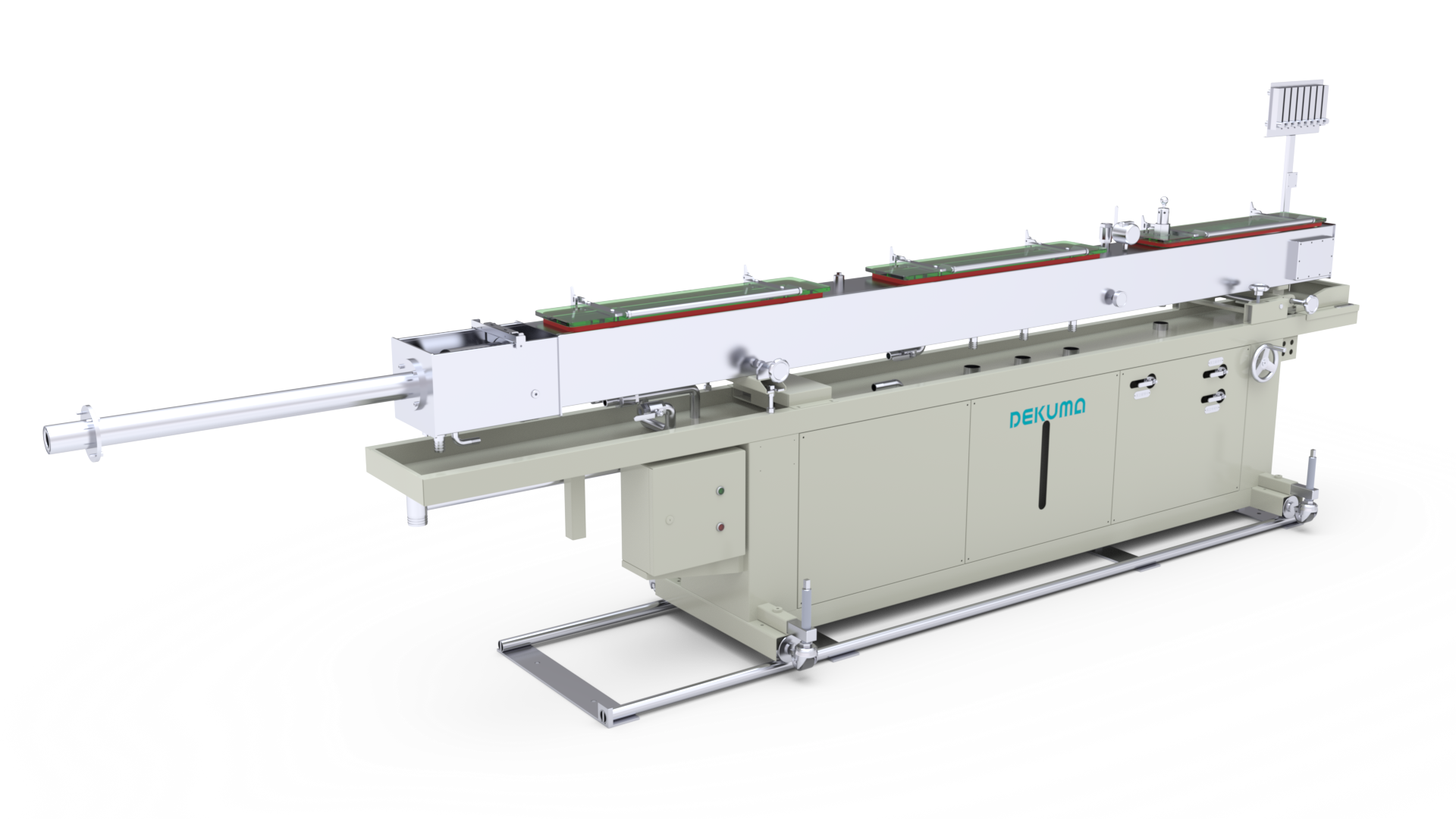

DEKUMA’s TPV Extrusion Line: Enhancing the Way

DEKUMA’s TPV extrusion line is at the forefront of providing high-performance solutions for EV manufacturers. Designed to produce multi-layered hoses with exceptional durability, DEKUMA’s extrusion technology enables the creation of TPV hoses that meet stringent industry standards. By integrating cutting-edge TPV pipe extrusion technology, DEKUMA is helping EV manufacturers enhance their fluid pipeline systems with robust, lightweight, and eco-friendly products. With precision engineering and advanced features, DEKUMA’s TPV extrusion line ensures high throughput and consistent quality.

Optimizing Efficiency with TPV Knitted Reinforced Hose Extrusion Line

DEKUMA’s TPV knitted reinforced hose extrusion line offers a sustainable and efficient solution for producing multi-layered hoses used in EVs. This advanced system combines TPV with knitted layers (such as polyester or aramid) to create high-strength, flexible hoses capable of handling demanding automotive fluid systems.

Conclusion

With DEKUMA’s TPV extrusion line, manufacturers can optimize their production processes, increasing output while maintaining the highest quality standards. By providing reliable, long-lasting hoses, DEKUMA supports the continued growth of the electric vehicle market.